Hand Boer "HDT-5"

The most powerful and durable in its class

(delivery anywhere in the world)

| Data for configuration of the hand boer HDT-5 for well drilling | |

| Equipment | Price, $ (€) |

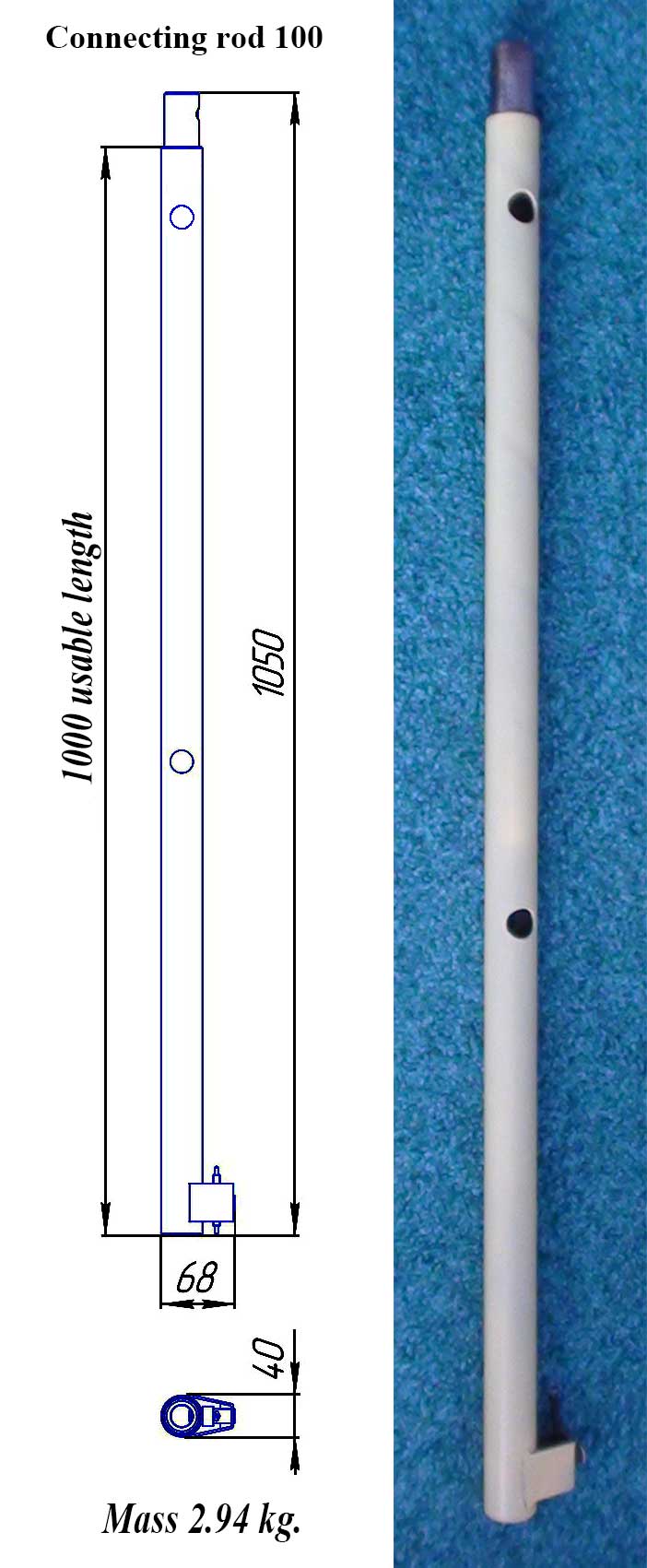

| Connecting rod 100** | 37.50 (37.50) |

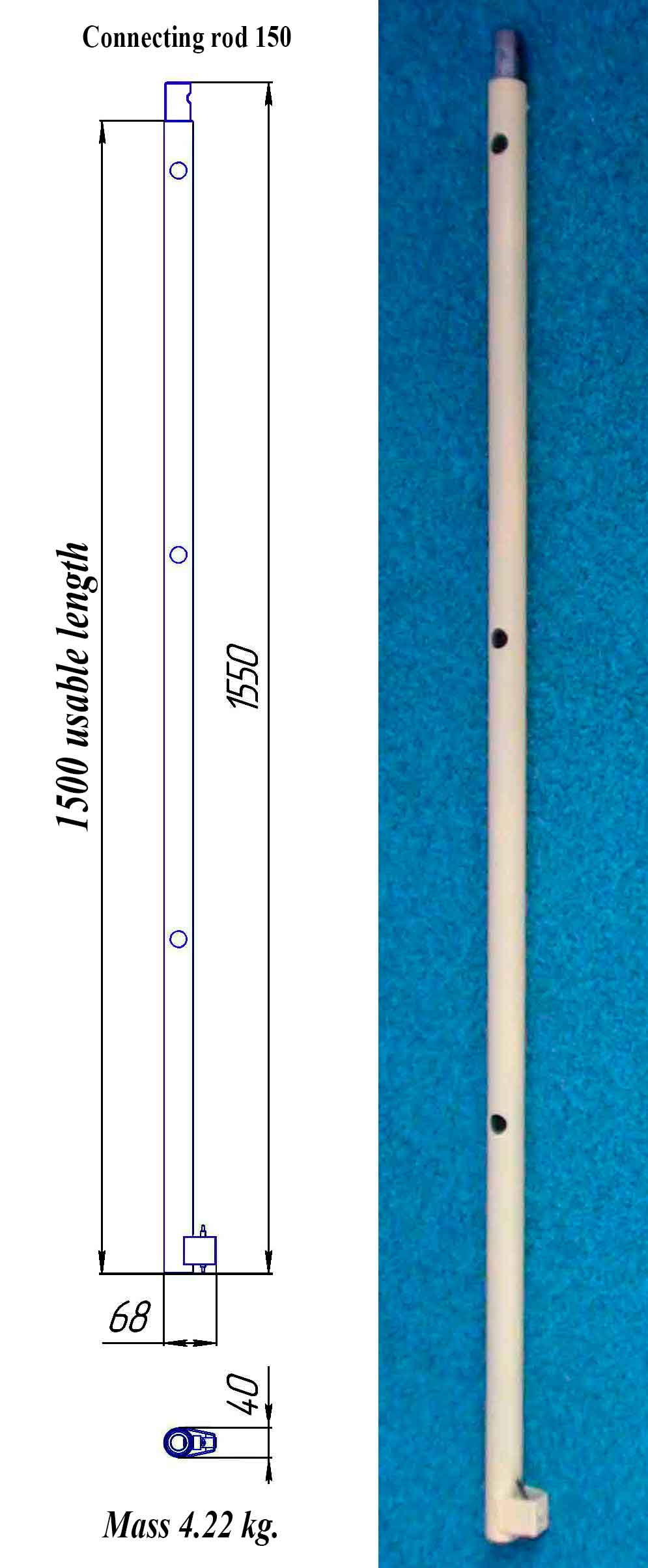

| Connecting rod 150** | 45.00 (45.00) |

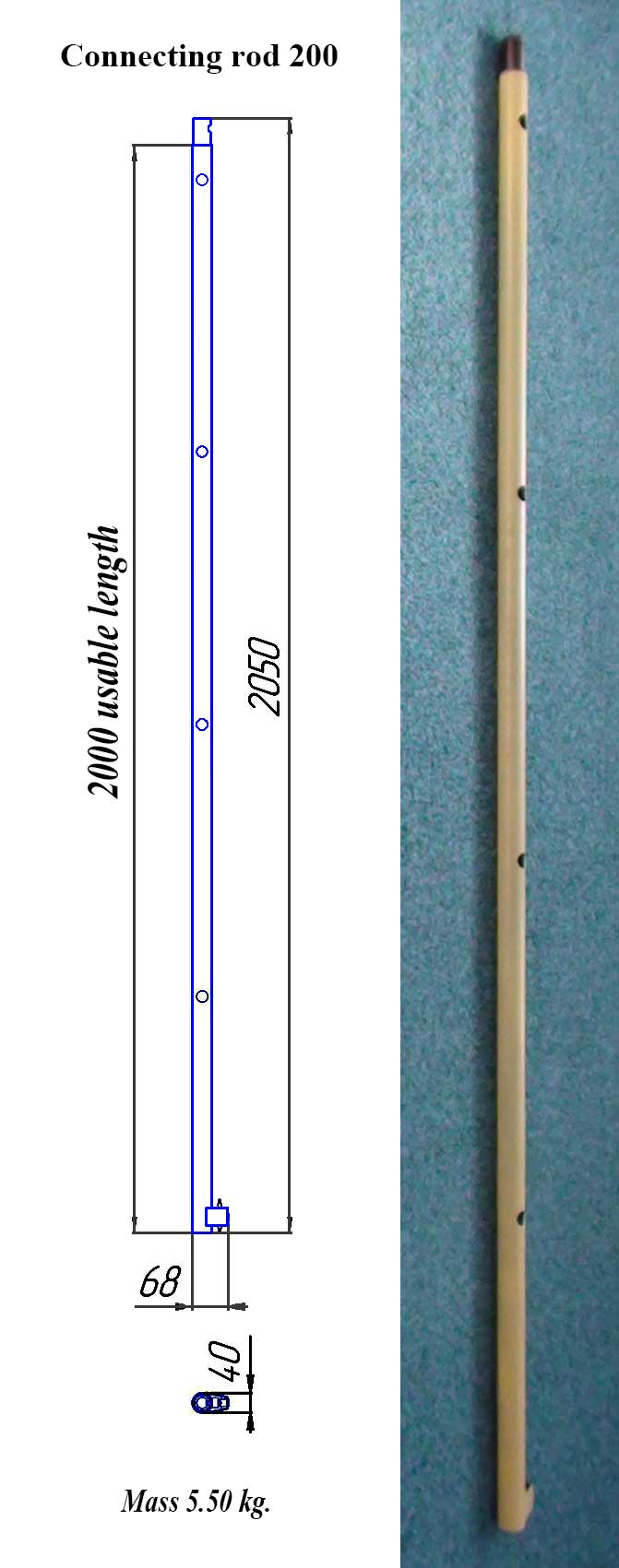

| Connecting rod 200** | 52.50 (52.50) |

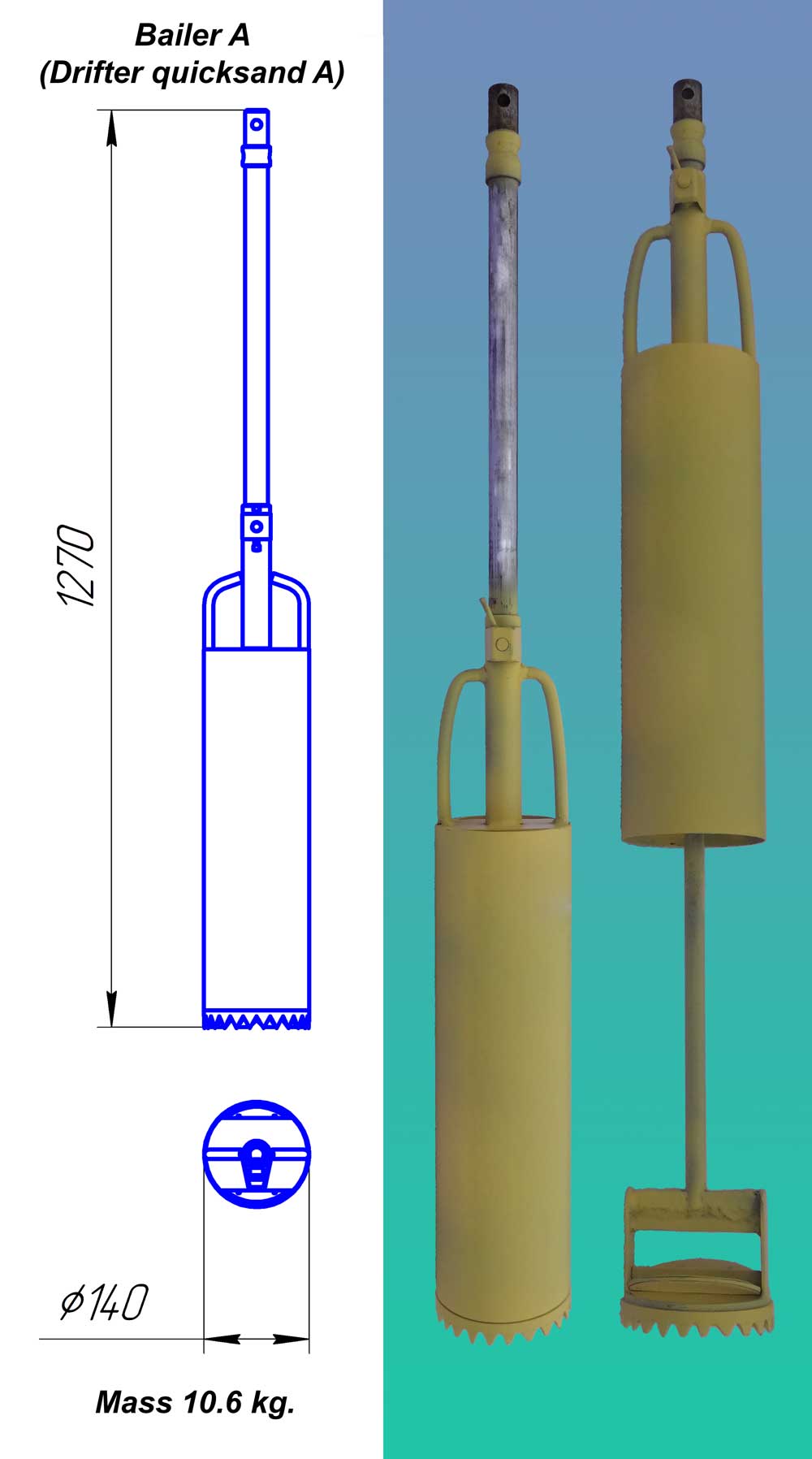

| Bailer A (Drifter quicksand A) | 212.50 (212.50) |

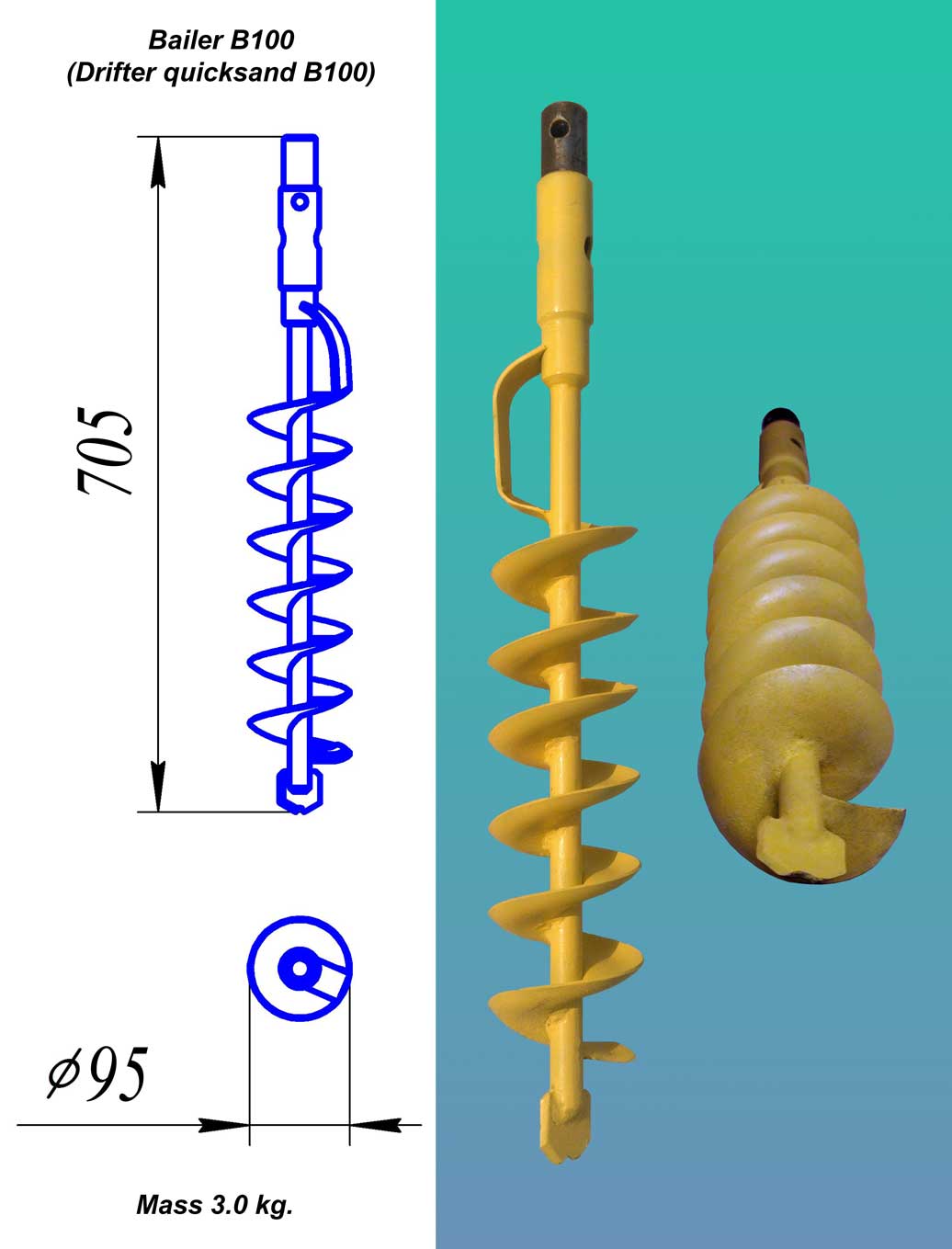

| Bailer B100 (Drifter quicksand B100) | 212.50 (212.50) |

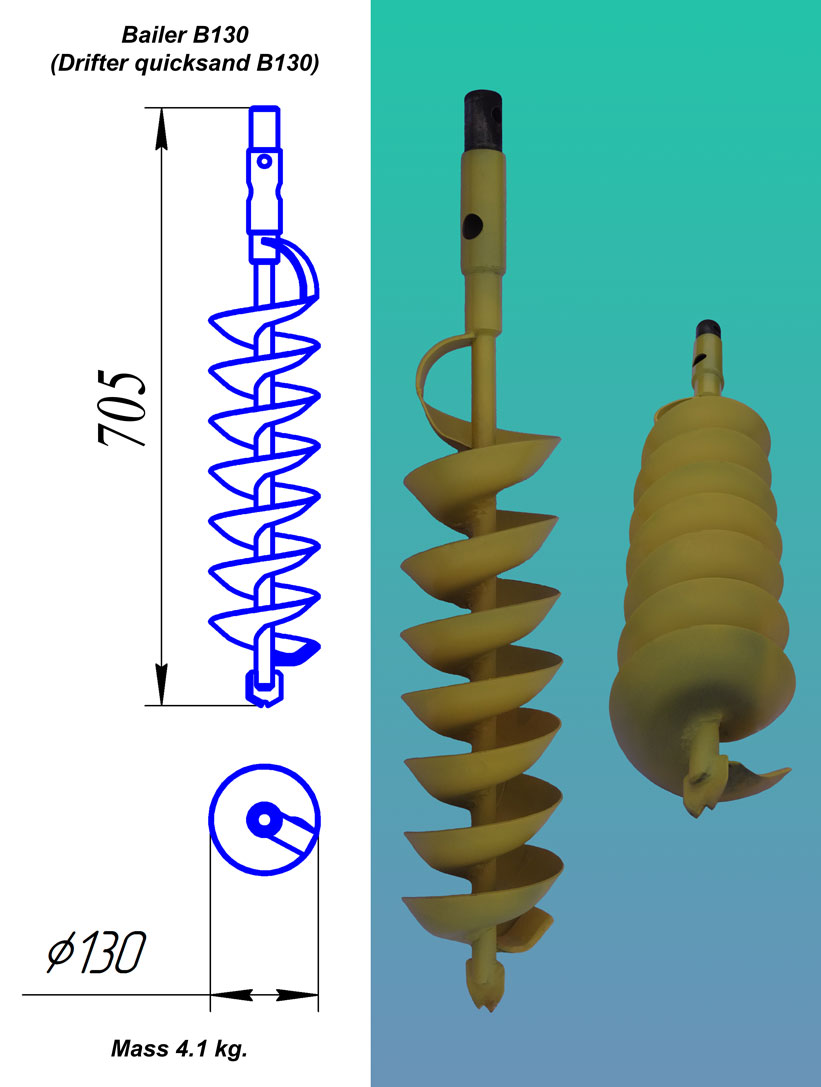

| Bailer B130 (Drifter quicksand B130) | 212.50 (212.50) |

| Equipment «Well 10-200»

for drilling to a depth of 10 meters, with a diameter of 200 mm. under the plastic casing pipe with a diameter of 160 mm |

|

| Drill rod 200* | $ 55.00 (€ 55.00) |

| Handle | $ 30.00 (€ 30.00) |

| Connecting rods 50** |

$ 27.50 х 3 = $ 82.50 (€ 27.50) х 3 = (€ 82.50) |

| Connecting rods 200** |

$ 52.50 х 4 = $ 210.00 (€ 52.50) х 4 = (€ 210.00) |

| Extender |

$ 7.50 х 2 = $ 15.00 (€ 7.50) х 2 = (€ 15.00) |

| Spatula | $ 7.50 (€ 7.50) |

| Interception |

$ 7.50 х 2 = $ 15.00 (€ 7.50) х 2 = (€ 15.00) |

| Price: $ 415.00 (€ 415.00) | |

| Equipment for drilling to a depth of 8 meters | |

| Drill rod 100* | $ 55.00 (€ 55.00) |

| Handle | $ 30.00 (€ 30.00) |

| Connecting rods 50** |

$ 27.50 х 3 = $ 82.50 (€ 27.50) х 3 = (€ 82.50) |

| Connecting rods 200** |

$ 52.50 х 3 = $ 157.50 (€ 52.50) х 3 = (€ 157.50) |

| Extender |

$ 7.50 х 2 = $ 15.00 (€ 7.50) х 2 = (€ 15.00) |

| Spatula | $ 7.50 (€ 7.50) |

| Interception |

$ 7.50 х 2 = $ 15.00 (€ 7.50) х 2 = (€ 15.00) |

| Price: $ 362.50 (€ 362.50) | |

| Equipment for drilling to a depth of 6 meters | |

| Drill rod 300* | $ 55.00 (€ 55.00) |

| Handle | $ 30.00 (€ 30.00) |

| Connecting rods 50** |

$ 27.50 х 3 = $ 82.50 (€ 27.50) х 3 = (€ 82.50) |

| Connecting rods 200** |

$ 52.50 х 2 = $ 105.00 (€ 52.50) х 2 = (€ 105.00) |

| Extender |

$ 7.50 х 2 = $ 15.00 (€ 7.50) х 2 = (€ 15.00) |

| Spatula | $ 7.50 (€ 7.50) |

| Interception |

$ 7.50 х 2 = $ 15.00 (€ 7.50) х 2 = (€ 15.00) |

| Price: $ 310.00 (€ 310.00) | |

Technical parameters:

Connecting rod 100

Useful length 1 m. Weight 2.94 kg.

Connecting rod 150

Useful length 1.5 m. Weight 4.22 kg.

Connecting rod 200

Useful length 2 m. Weight 5.50 kg.

Selection of connecting rods:

In the configuration examples are given using the connecting rods 50 and 200. If you use only 200 rods, the cost of the well will decrease, but the convenience of drilling will significantly decrease. Since, when moving the handle in increments of 2 meters to drill is quite difficult. In addition, the use of 200 connecting rods may be difficult for other reasons, such as transportation in the car, the height limit at the drilling site, etc. In this regard, when planning the purchase of equipment, it sometimes makes sense to purchase transition rods of shorter length, but more convenient to use for this particular case.

Bailer A (Drifter quicksand A)

Technical parameters:

Length 1 m 27 cm. Weight: 10.6 kg.

The minimum diameter of the casing pipe, which can be used 150 mm.

The maximum amount raised quicksand 7.1 liters.

Serves for lifting of liquid, dense and loosened fractions of soil. Not intended for lifting dense sand and gravel.

Application:

Lower the bailer A (drifter quicksand A) to the quicksand and push to a depth of 50-60 cm, but not more. To facilitate the sinking, rotate the bailer in different directions together with the indentation. At the same time, if the depth does not exceed 15 cm, it is necessary to apply the bailer B130 (drifter quicksand B130), or it means that the quicksand is over.

After lifting the bailer A (drifter quicksand A) open the standard lock HDT and raise the glass up (example in the photo below), this will clean the bailer. For further use, lower the glass down and close the lock.

Bailer B100 (Drifter quicksand B100)

Technical parameters:

Length 66.5 cm. Weight: 3.0 kg.

The minimum diameter of the casing pipe, which can be used 100 mm.

The maximum amount raised quicksand 2.1 liters.

It serves for loosening and lifting of dense sand and fine gravel with a fraction of up to 20 mm. With an increase in the diameter of the well, increase the size of hard rocks, which can be retrieved with the help of the bailer B100 (drifter quicksand B100). On a well with an internal diameter of 150 mm, the maximum size of the extracted hard rocks can be between 100 - 120 mm in one or two dimensions and not more than 40 mm in the third. When working through the water column, if the quicksand is not fluid (for example, clean sand without clay impurities), lifting exercise is not faster 0.2 m/s, in order to avoid flushing. In General, by increasing the fraction of quicksand, the performance of the bailer falls.

The need to use bailers glass type in wells with a diameter 105-120 mm, followed the bailer B100 (drifter quicksand B100), to date, it has not been identified. Because the rest of the quicksand has such a fluid consistency, which is easily pumped out by submersible vibration pumps.

Application:

Lower the bailer B100 (drifter quicksand B100) to quicksand and screw in the quicksand to a depth of not more than 45-50 cm. When screwing, lift the bailer slightly from time to time to facilitate the screwing and to check that the bailer is not screwed into the quicksand too hard and can be lifted.

At sinking of the bailer through a casing pipe, to make a draught of a pipe at the time of lifting of the bailer.

If, after a slow rise through the water column, the bailer is clean, the remaining part of the quicksand can be pumped out with a vibration pump. At the same time to track on pumped out consistence that the quicksand was not too dense (in order to avoid breakage of the pump), a sign of thickening is a sharp drop in the volume of the pumped quicksand. In this case, you can continue to use the bailer. This recommendation applies to wells with an internal diameter of 105-120 mm and a depth of up to 12 meters.

Bailer B130 (Drifter quicksand B130)

Technical parameters:

Length 71.5 cm. Weight: 4.1 kg.

The minimum diameter of the casing pipe, which can be used 140 mm.

The maximum amount raised quicksand 4.5 liters.

Is used for loosening and lifting of dense sand and fine gravel with a fraction of up to 20 mm. Possible fence and larger fractions, up to 40 mm, but at the same time the occupancy of the bailer sharp drop. When working through the water column, if the quicksand is not fluid (for example, clean sand without clay impurities), rise not be implemented quickly. 0.2 m/s, in order to avoid flushing. Otherwise requires after themselves use of the bailer A.

Application:

Lower the bailer B130 (drifter quicksand B130) to the quicksand and screw in the quicksand to a depth of not more than 45-50 cm. When screwing, lift the bailer slightly from time to time to facilitate the screwing and to check that the bailer is not screwed into the quicksand too hard and can be lifted.

At sinking of the bailer through a casing pipe, to make a draught of a pipe at the time of lifting of the bailer.

If, after a slow rise through the water column, the bailer is clean, the remaining part of the quicksand is better to remove with the help of the bailer A. Application in this case, the vibration pump is not as effective as in wells with an internal diameter of 105 – 120 mm, due to the large amount of remaining silt.

Selection of bailers (drifters quicksand) and recommendations for use of the casing

Simple case of drilling

When drilling a well, loam with inclusions of solid rock up to 5 cm is removed, that no other equipment except that given in the examples You will not need.

You reach the aquifer and in the well begins to rise sharply water. Sometimes the water does not rise, but after its appearance it can not be pumped out. It also means that You have reached the aquifer.

In these cases, it makes sense to deepen another meter, and preferably two, if possible, below the water mirror and lower the casing.

The important point is that after drilling the well went raw rock, it is impossible to stop and postpone the completion of the well the next day, it can be collapse and all the work done will be in vain.

Quicksand

If you got a quicksand when drilling a well, then using a conventional drill is not something that pass, even delve into it will not succeed. It is necessary to use a bailer or a drifter quicksand.

There are three main options.

A. True quicksand (mushy clay-sand suspension).

True quicksand is pressed the casing and then, already from the well casing is removed the bailer A (drifter quicksand A), or vibration pump depending on the diameter of the well.

B. False quicksand (water-saturated sand) the well before the start of the quicksand is dry.

The false quicksand is removed by the bailer B (drifter quicksand B) with a simultaneous draft of the casing (an example is given in the video). The number of the bailer is selected depending on the diameter of the well.

B. False quicksand (water-saturated sand) while the well is filled with water (for example, as a result of high groundwater).

In this case, the quicksand is also selected by the bailer B (drifter quicksand B) with a simultaneous draft of the casing, but with the sand from the bailer B (drifter quicksands B) will slip away, and after his recovery, already loosened sand is selected or bailer A (drifter quicksands A) or a vibrating pump, depending on the diameter of the well.

Ultimately.

The choice of bailer or drifter quicksands can be most accurately done after You have stumbled upon this quicksand, if ever you found it. Since the well is drilled very quickly and eight-meter wells, for example, for a work shift, you can drill a couple of pieces (so quickly they are drilled only by our drill), this is a justified approach.

If You don't want to waste time on the rebuy bailer (drifter quicksands), then to the normal kit you can immediately get the bailer B (drifter quicksands B), and with high probability we can expect the normal creation of the well on the sandy quicksand. The number of the bailer is selected depending on the planned diameter of the well.

Recommendations for use of the casing pipe:

The drifters quicksands are designed for casing pipes with the smallest internal diameter of 100 mm. these are the most common PVC sewer pipes. The casing may be of larger diameter. This is not of fundamental importance, since a quicksands is a formless phenomenon, however, the greater the difference between the inner diameter of the casing and the diameter of the drifters quicksands, the slower the drilling.

If the selected casing pipe of PVC 160х4,0 it is necessary to bear in mind the following circumstance. Only the smooth part of the section of such pipe can be loaded into the quicksand. These pipes are produced in sections from 1 to 6 meters long. Therefore, when diving into the long section of the quicksand, you will need a few meter sections, because for example, through the protruding two-meter section to do something extremely difficult.

Wells may have a tendency to silt. The connecting rods and bailers (drifters quicksands) used to create the wells, are the guarantors at any time, with their help, it is possible to clean the well and restore the water yield. For normal re-use of equipment, before starting storage, it is necessary to wash off the dirt and lubricate the connecting elements with grease.

Contacts for questions: configuration, application, delivery, etc.